MEA Hydrogenated Nitrile Butadiene Rubber Industry Outlook 2025–2035

Hydrogenated nitrile butadiene rubber industry analysis in the mea is projected to grow from USD 135.0 million in 2025 to USD 209.7 million by 2035

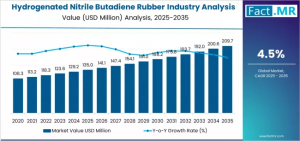

ROCKVILLE, MD, UNITED STATES, November 28, 2025 /EINPresswire.com/ -- The hydrogenated nitrile butadiene rubber (HNBR) industry in the Middle East & Africa (MEA) is poised for meaningful expansion over the next decade, underpinned by growing demand across automotive, oil & gas, industrial, and infrastructure sectors. HNBR, a high-performance elastomer known for superior resistance to heat, oil, chemicals and mechanical stress, is increasingly used for seals, gaskets, hoses, timing belts and other critical components requiring long-term durability under demanding conditions.It is anticipated that the MEA's need for hydrogenated nitrile butadiene rubber would increase.The MEA's demand for hydrogenated nitrile butadiene rubber is expected to expand by USD 75 million over the course of the forecast period, from USD 135 million in 2025 to over USD 210 million by 2035. With the market growing at a compound annual growth rate (CAGR) of 4.5% between 2025 and 2035, this indicates a total growth of 55.6% throughout the decade.

From USD 135 million in 2025 to roughly USD 210 million by 2035, there was an absolute rise of USD 75 million during the predicted period. Over the course of ten years, the market has grown at a compound annual growth rate (CAGR) of 55.6%.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=11966

Key Regional Highlights & Demand Drivers

MEA currently represents a modest but fast-growing share of the global HNBR market, with several regional economies showing above-average growth potential.

Primary demand drivers include automotive component manufacturing, oil & gas operations, industrial machinery needs, and the broader trend toward long-lasting, performance-oriented materials.

Specific drivers:

Automotive sector growth: HNBR is widely used for O-rings, seals, hoses, and belts in vehicles, offering resistance to oils, fuels, heat and mechanical wear — attributes critical for modern engines, transmissions, and emission-compliant components.

Oil & gas and energy applications: HNBR’s chemical resistance and thermal stability make it ideal for sealing solutions, downhole components, blowout-preventer parts and pipeline systems used in hydrocarbon extraction and processing.

Industrial machinery and hydraulics: HNBR finds broad use in hydraulic seals, compressor components and fluid-handling systems where durability under pressure and chemical exposure is essential.

Preference for long service life: As regional industries modernize, there is growing demand for materials that minimize maintenance and downtime; HNBR’s longevity fits this requirement.

Technical Advantages

HNBR offers several material advantages over conventional elastomers:

Excellent resistance to oils, fuels and aggressive hydrocarbon fluids, critical for automotive and oilfield uses.

High thermal stability and durability across broad temperature ranges, supporting reliable performance in high-heat environments.

Superior mechanical strength, abrasion resistance and dimensional stability, resulting in long service life for seals and components.

Compatibility with demanding operating conditions—high pressure, chemical exposure and fluctuating temperatures—making HNBR adaptable across sectors.

Challenges & Market Constraints

Despite favorable fundamentals, the HNBR industry in MEA faces constraints:

Limited local production capacity: Many MEA markets rely on imports for HNBR, increasing landed costs and creating supply-chain vulnerabilities for component manufacturers.

Price sensitivity: In cost-conscious segments, cheaper elastomers may be preferred over HNBR where premium performance is not strictly required.

Technical expertise gap: Proper compounding, sealing design, and material selection require specialized knowledge; lack of local expertise can slow adoption.

Competition from alternatives: Standard nitrile rubber and other elastomers may compete where cost considerations outweigh performance needs.

Strategic Recommendations

For Producers & Suppliers

Evaluate establishing regional compounding or manufacturing facilities (in hubs like Saudi Arabia, UAE or South Africa) to reduce import costs and improve supply resilience.

Develop application-specific HNBR grades (e.g., high-temperature, sour-gas resistant, heavy-duty hydraulic seals) in collaboration with OEMs and energy firms.

Provide technical support, training and after-sales services to local manufacturers and end users to accelerate adoption.

For End-Use Industries

Prioritize HNBR for critical applications—engines, fuel and hydraulic systems, downhole equipment—where reliability and long lifetimes reduce total cost of ownership.

Factor lifecycle benefits (fewer failures, lower downtime) into procurement decisions, recognizing that higher upfront costs are often offset by longer service intervals.

Partner with trusted suppliers to ensure consistent material quality and appropriate grade selection for local operating conditions.

For Investors & New Entrants

View HNBR as a niche but high-potential market in MEA, especially where automotive manufacturing, oil & gas operations, and industrial modernization are priorities.

Target value-chain gaps: regional compounding, local distribution, custom formulation and technical services offer differentiated business models.

Align strategies with long-term regional infrastructure and energy investments to capture sustained demand growth.

Market Outlook to 2035

Over the next decade, the HNBR market in MEA is expected to grow steadily as regional industrialization, automotive assembly, and energy projects expand. As local production and technical capabilities strengthen, HNBR adoption will likely broaden from premium, high-performance applications into wider industrial uses such as hydraulics and manufacturing equipment. Suppliers that localize supply, offer tailored formulations, and provide technical support will be best positioned to capture demand and build a sustainable presence in the region.

Purchase Full Report for Detailed Insights:

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here: https://www.factmr.com/checkout/11966

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us – sales@factmr.com

To View Related Report:

Hydrogenated Cosmetic Ingredients Market: https://www.factmr.com/report/hydrogenated-cosmetic-ingredients-market

Hydrogenated Nitrile Butadiene Rubber Market: https://www.factmr.com/report/2534/hydrogenated-nitrile-butadiene-rubber-market

Hydrogenated Nitrile Butadiene Rubber Industry Analysis in the UK: https://www.factmr.com/report/united-kingdom-hydrogenated-nitrile-butadiene-rubber-industry-analysis

Adiponitrile Market: https://www.factmr.com/report/4486/adiponitrile-market

About Fact.MR

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth

S. N. Jha

Fact.MR

+1 628-251-1583

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.